设计原则:简化操作流程

Production management system interfaces emphasize simplifying complex workflows. By integrating core functions into intuitive icons and menus, users can quickly access tasks such as order tracking, inventory management, and quality control. Visual aids like progress bars and color-coded alerts enhance clarity, reducing training time for new employees.

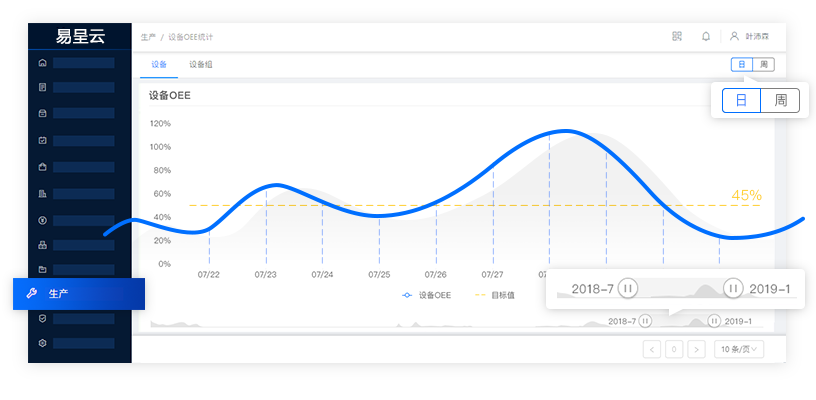

核心功能模块与可视化布局

well-designed interface typically includes dashboards that consolidate real-time data from production lines, material usage, and equipment status. Drag-and-drop task assignment modules and dynamic charts allow managers to adjust schedules and allocate resources efficiently. Hierarchical menus ensure that both high-level overviews and granular details are accessible within two clicks.

用户体验与自定义设置

User experience is optimized through responsive design and role-based customization. Operators may prioritize quick-access buttons for machine controls, while supervisors focus on analytics screens. Personalizable widgets and saved templates enable users to tailor the interface to their daily needs, improving both comfort and productivity.

生产管理系统界面的设计难点是什么

Balancing functionality with simplicity remains a key challenge. Designers must accommodate diverse user roles—from factory-floor workers to executives—without overwhelming any group. Ensuring real-time data synchronization across global teams while maintaining low latency further complicates interface architecture.

如何通过界面设计降低误操作风险

Strategic use of confirmation dialogs for critical actions and automated input validation prevent accidental errors. Color-blind-friendly palettes and tactile feedback mechanisms (e.g., vibration on button press) enhance accessibility. Permission-based UI elements dynamically hide or disable functions irrelevant to current user roles.

界面响应速度对生产管理的影响

Slow response times in material requisition screens or delay in equipment status updates can cascade into production bottlenecks. Optimized data caching strategies and edge computing integration ensure sub-second refresh rates for high-priority modules, maintaining seamless coordination between digital systems and physical operations.

多工厂协同生产的界面设计要点

Unified time-zone displays, multi-language quick-switch options, and comparative analytics panels enable efficient cross-facility management. Geo-tagged equipment status indicators and collaborative annotation tools allow distributed teams to troubleshoot issues collectively. Automatic conflict detection alerts prevent overlapping resource allocations.

未来界面如何融合AR与物联网技术

Augmented reality overlays will soon guide technicians through equipment repairs using 3D diagrams superimposed on physical machines. IoT sensor data may trigger auto-populated maintenance tickets within the interface. Voice-controlled navigation and gesture recognition could replace traditional input methods in hazardous environments.